In our latest instalment of our Your Questions Answered series, we explore the subject of Dry Rate Testing. During our recent Dry Rate Testing webinar, we were asked a number of interesting and informative questions. We have compiled the answers for you to read below. The key topics covered were:

- To claim 'quick-drying', do 199, 200 and 201 all need to be performed?

- Would the drying rate vary for elastane fabric?

- Variance in drying rate for Nylon or blend fabrics

- Test methods for moisture management performance

- Chemical finish

- Which AATCC method is most suitable for analysing wool fabric?

- Dry Rate Testing based on various specimens

- Can you test things other than apparel?

- Testing multi layered fabric

- Thermal properties on the fabric with Dry Rate Testing

- Can you complete Dry Rate Testing for Socks?

Q: To claim a fabric as 'quick-drying', do 199, 200 and 201 all need to be performed?

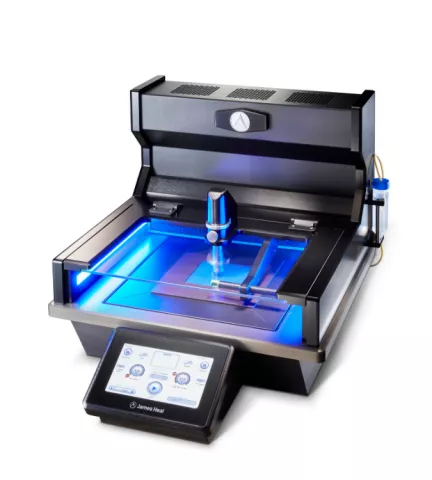

A: Essentially, no. These test methods are used dependant on what you are trying to achieve. When looking at an 'activewear legging' material we would focus specifically on the 201 test as the heated plate is set to the temperature of the human body and includes air flow representative of the environment. This test best represents in-use conditions and is the most appropriate for the specimen.

Q: Would the drying rate vary for elastane fabric?

A: We know that if you test a fabric with stretch properties or that is designed to stretch, such as yoga or gym leggings, the test result does change depending on whether the fabric is relaxed or under tension. This is really important for performance wear fabrics as you need to know how the fabric performs in situ.

Q: Would you see a variance in drying rate for Nylon or blend fabrics?

A: As you change the fibre composition, the drying rate does change based on the textile construction, the fibre content and the garment construction. Every single one of those properties adds a different variable so it is safe to say that any variable that changes from fabric to fabric will impact the results of the test.

Q: What test method gives better indication of moisture management performance, AATCC 195 or doing both AATCC 197 and 201?

A: If you want to look at a fabrics overall moisture management properties, you would want to test for wicking and drying rate. These are different functions within a fabric, so you would want to look at a combination of both test methods to get the best results.

Q: Does a chemical finish help?

A: It depends what the finish is. If, for example, you have a water repellent finish on the fabric and you applied water to the underside of it, it would have a potential to repel the water, so the fabric wouldn't dry and could cause discomfort to the user. The answer to this question is dependant on what treatment you are referring to and exactly what chemical.

Q: Which AATCC method, 199, 200 or 201 is most suitable for analysing wool fabric?

A: All the methods are slightly different but would all be appropriate. The choice of test would depend on whether you wanted to look at the air flow method or the heated plate method. It would depend on the product you are testing as to which method we would advise to use. If you want to read more about the different test methods, we recommend this research article in the Journal of Engineered Fibers and Fabrics.

Q: Is this test typically for a single specimen tested for data collection to verify product quality, or is it based on an average over a series of specimens of the same product?

A: The AATCC 201 test is definitely for an average of various specimens. For example, if you are testing a garment you would take samples from different places such as the arm, the back, the chest and the side panel and then you would test those samples and take the average to measure the overall performance of the garment. Equally, if you are testing something that is a 3D component such as a sock, you would cut that and create various flat samples from it. The minimum for the test is 3 samples but ideally we recommend that you test 5 to understand properly how the product would work.

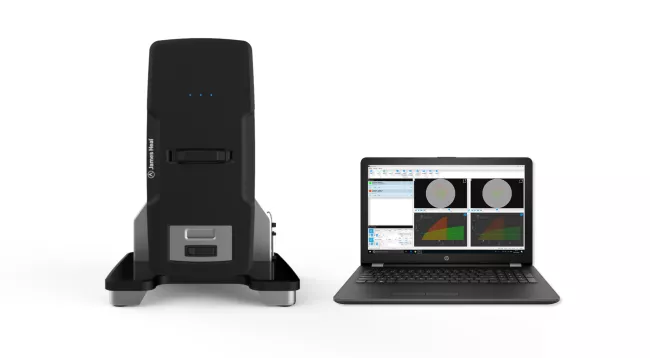

Q: Is this machine only for apparel, or could it be used to test other things from other industries?

A: Dry Rate Testing can definitely be used in other industries. Obviously, James Heal is more prominently known for textile testing and in the apparel sectors so we tend to apply it to these textiles when discussing the instrument, but essentially any material or product that comes into direct contact with the skin, such as wipes, towelling, bedding or mattresses could be tested by a Dry Rate Tester.

Q: How does it work when testing packages of material to see how they work together?

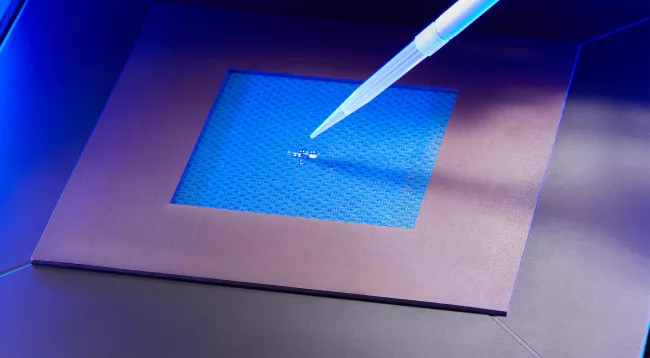

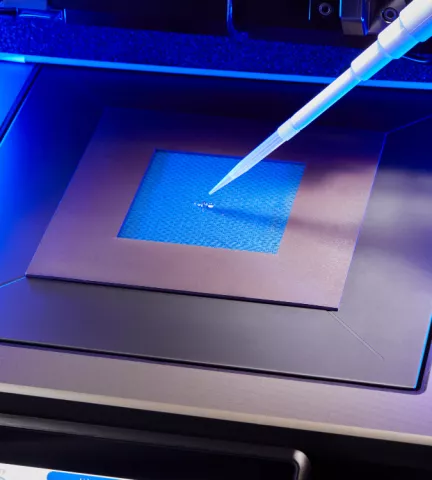

A: This is referring to testing a double or multiple layered fabric. Multi layered fabrics can be tested as individual layers or as a sandwich. The infrared probe at the centre of our dry rate tester can actually be height adjusted to ensure you are still maintaining the correct distance between the specimen and the probe itself to record the temperature.

Q: The machine maintains a temperature of 37 degrees celsius, but based on the thermal properties on the fabric, won't the heat fluctuate to maintain the temperate between sample to sample? If so, is that taken into consideration when thinking about the evaporating rate?

A: Yes, so if you have a multi-layer fabric which is a lot thicker than a single layer, the temperature of the sample itself will fluctuate. For a specimen that is a lot thinner, the water will be exposed all the way though much quicker so this will record differently to something a lot thicker. The absorption properties of the fabric can also impact the drying rate.

The heat will fluctuate and vary and you will be able to see that when you digitally track a variety of different samples, you can see how the graph will change from different materials and thicknesses.

Ultimately, the end of the test is measured when the physical temperature of the sample returns back up to body temperature, meaning the end point of the result would still be the same. What you may see happening is the steepness of the slope on the graph would change from sample to sample.

Q: We have an increasing interest in sock testing for Dry Rate, do you recommend heated plate for socks? They are usually very thick and absorb a large amount of water.

A: Dry Rate testing would definitely be suitable for sock testing. If you would like some guidance and more information on how to test the dry rate of socks please contact us and we would be happy to help.

We hope you have enjoyed this Q&A on Dry Rate Testing

If you missed this webinar, you can watch it On-Demand here at a time that suits you.