Brochure(s)

Got a question about this solution?

Get in touch and speak to one of our Technical Sales Engineers now...

Speak to an expert

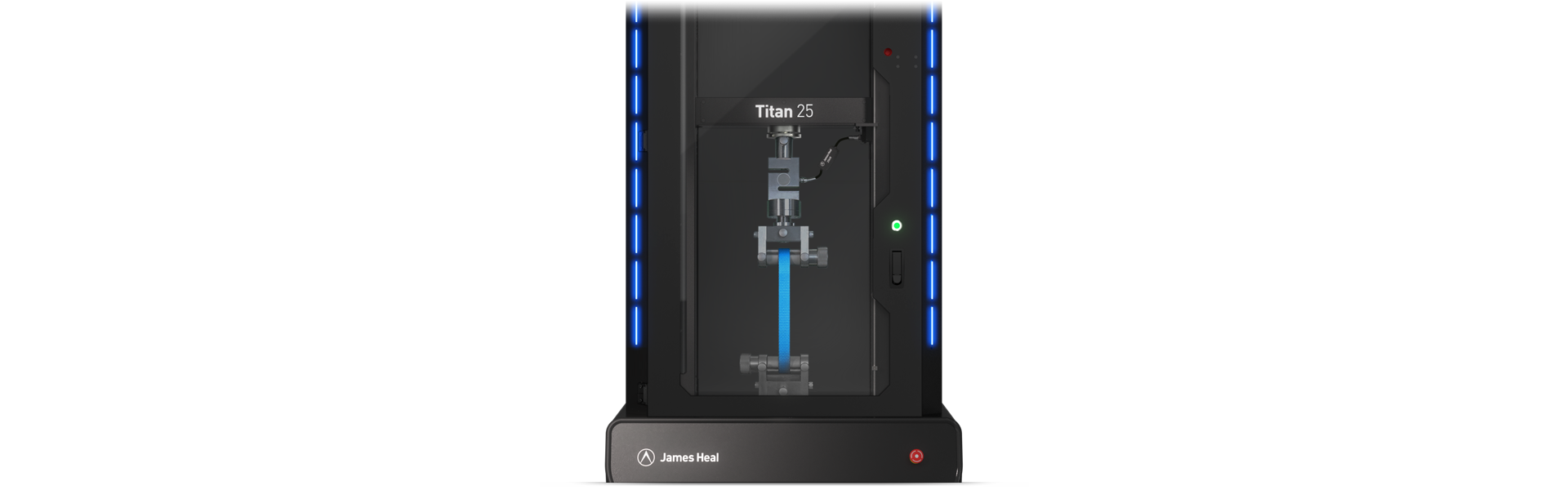

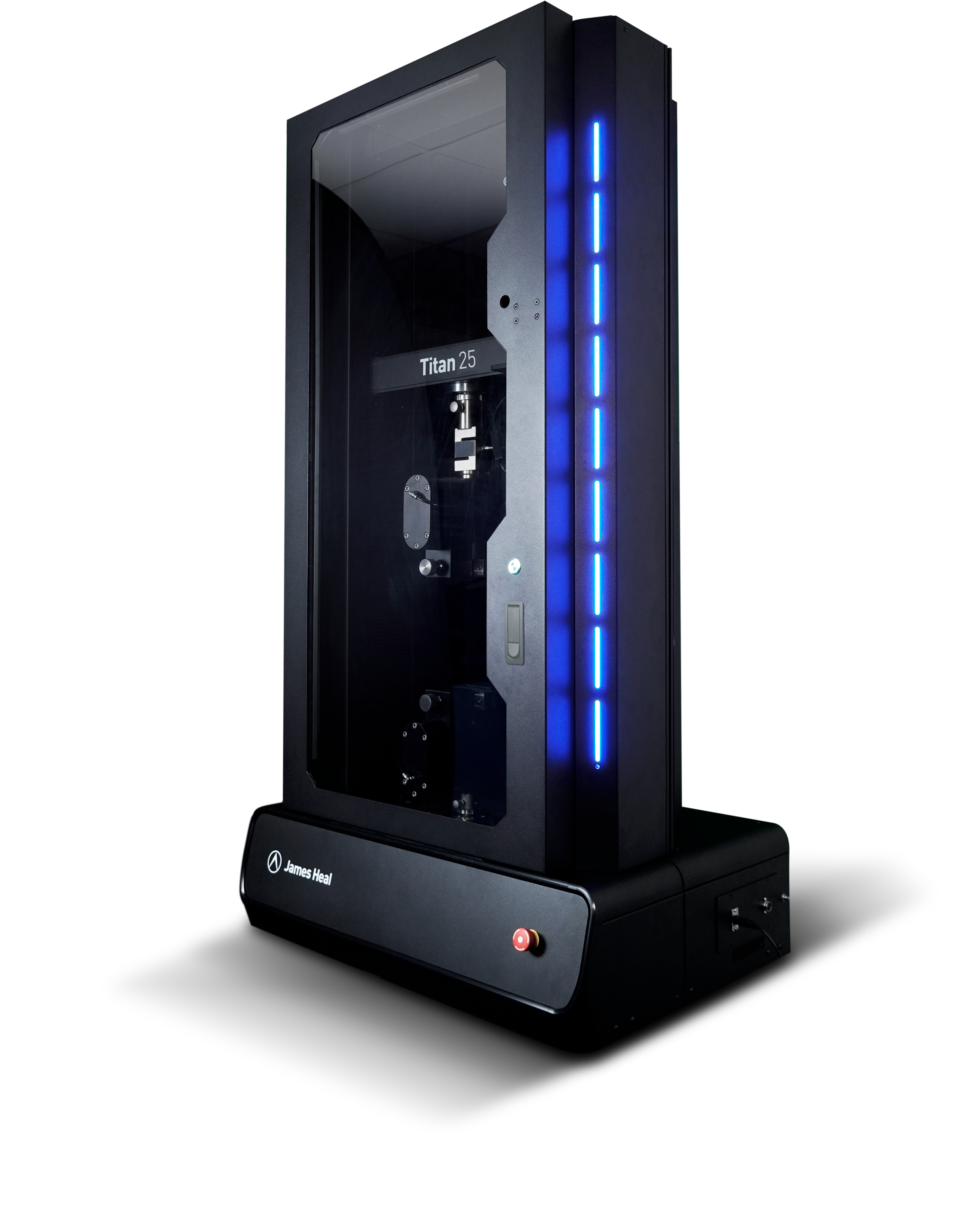

Where power meets precision

Titan 25 performs tensile and compression testing at our highest capacity yet, covering a broad catalogue of 750+ built-in standards.

Overview

Incorporating the latest advances in textile testing technology, our new Titan dual column universal testing machine is offered in both 10 kN and 25 kN capacities, ensuring versatility and effortless operation.

With TestWise™ software as its driving force, the Titan series guarantees unparalleled power, precision, and accuracy for conducting comprehensive tensile and compression strength evaluations of textiles. The Titan and TestWise™ comes equipped with over 750 pre-loaded standards and methods, alongside a wide selection of compatible tooling.

Discover the distinctive features of both Titan 10 and Titan 25 models.

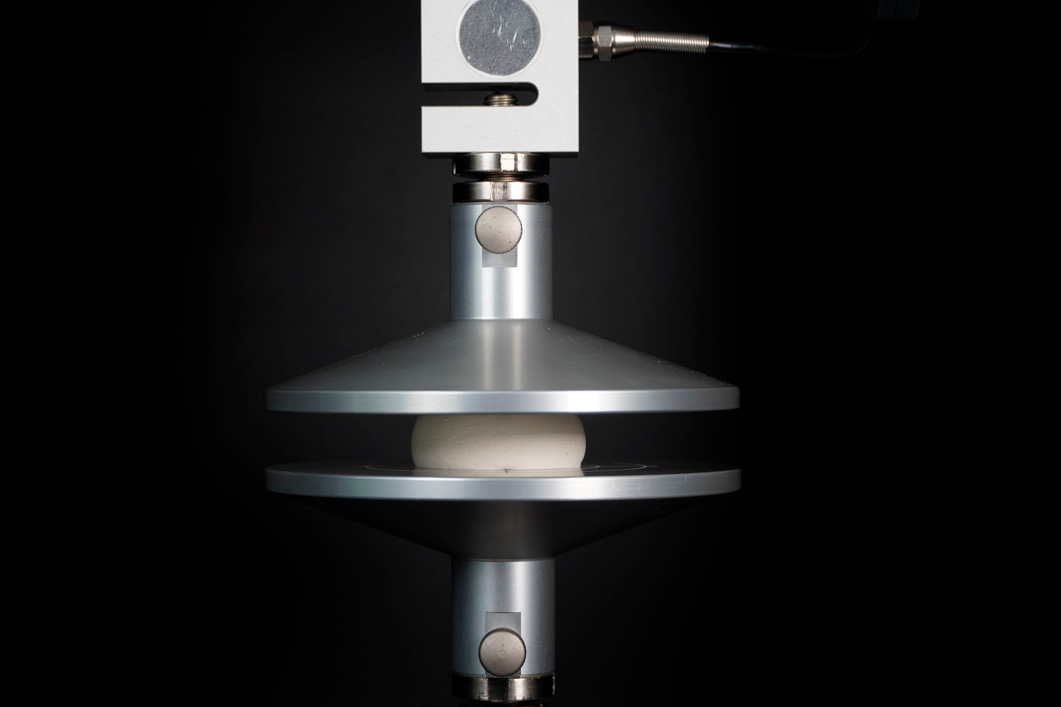

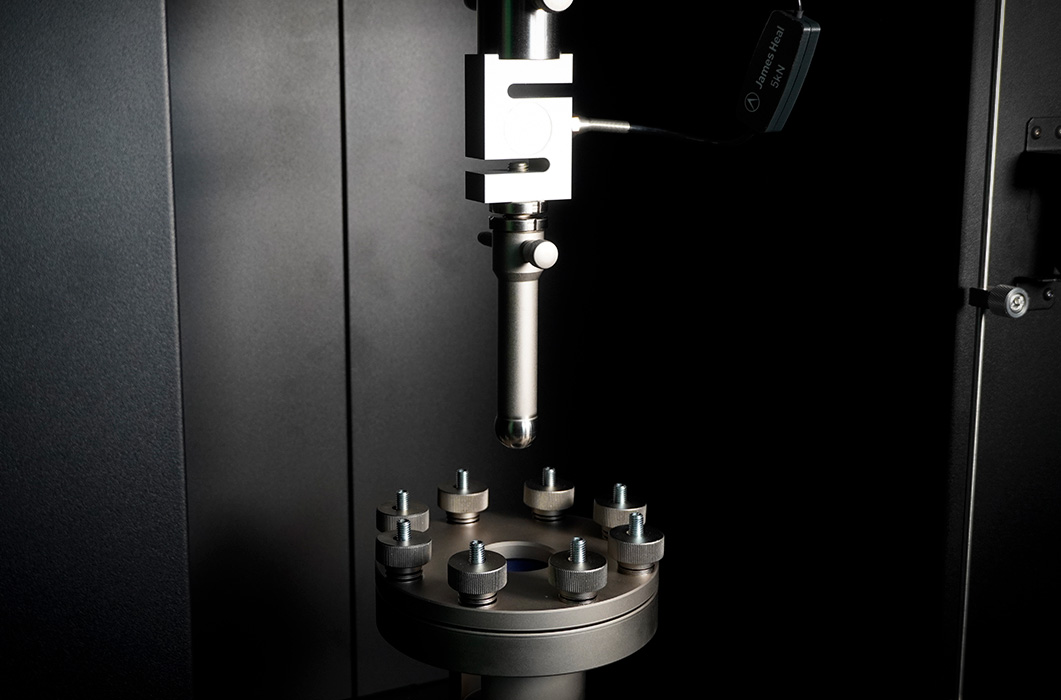

Interchangeable tools

Extensive range of tool-free accessories

These versatile dual column instruments enable testing on larger specimens across a wide range of tensile and compression tests.

The extensive range of tool-free specimen grips are interchangeable between Titan 5, Titan 10 and Titan 25 using a unique pin and post connection system. Load cells from 100N to 25kN allow testing to as low as 2N giving laboratories maximum flexibility and return for their investment.

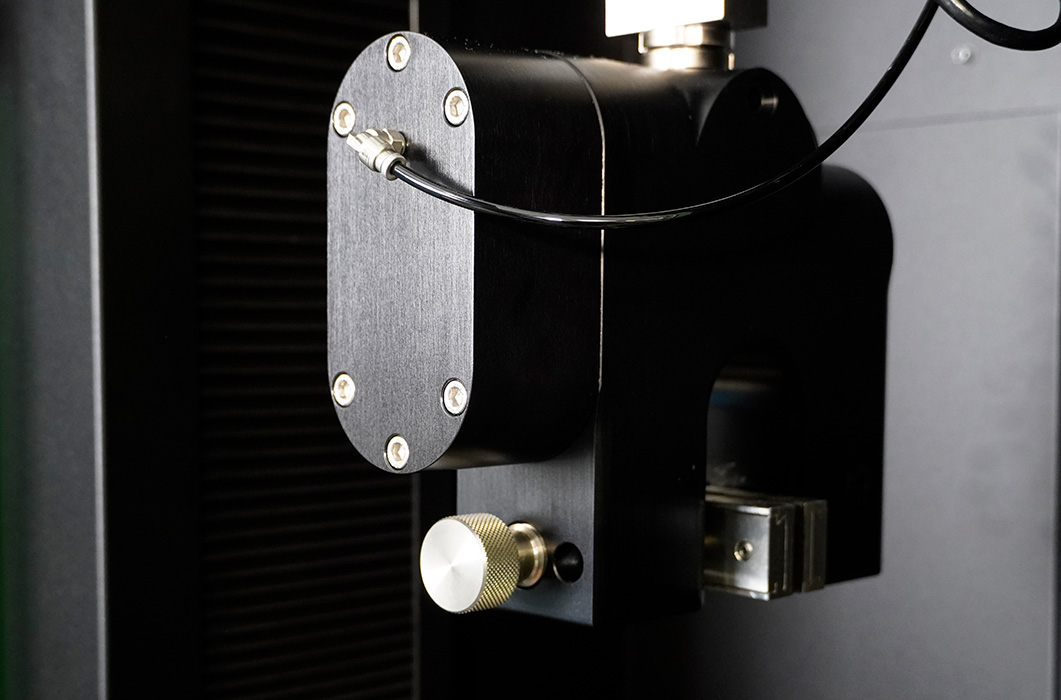

Effortless control

Improved manual testing

Titan 25 features an optional handheld controller for greater manual control during testing, especially useful when gripping test specimens of variable or irregular sizes. They can also be controlled using the foot pedal, or the TestWise software.

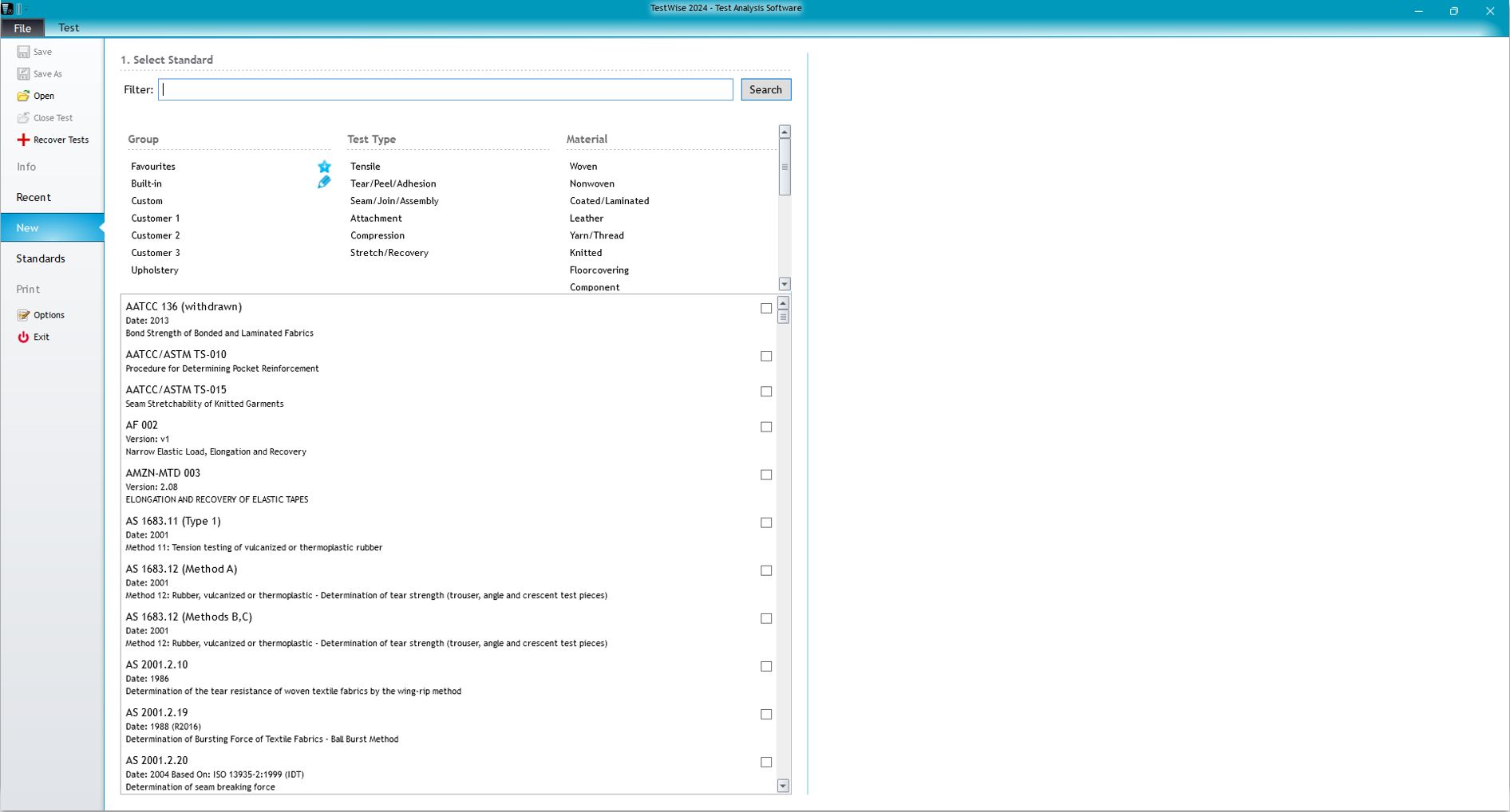

TestWise™

Advanced test software

Advanced test software that keeps things simple, for faster, smarter testing.

Features of TestWise include:

- over 750 pre-loaded standards and retailer methods

- filters and user favourites for quickly selecting tests

- pre-loaded test parameters

- export data to PDF and Excel

- minimal user training required

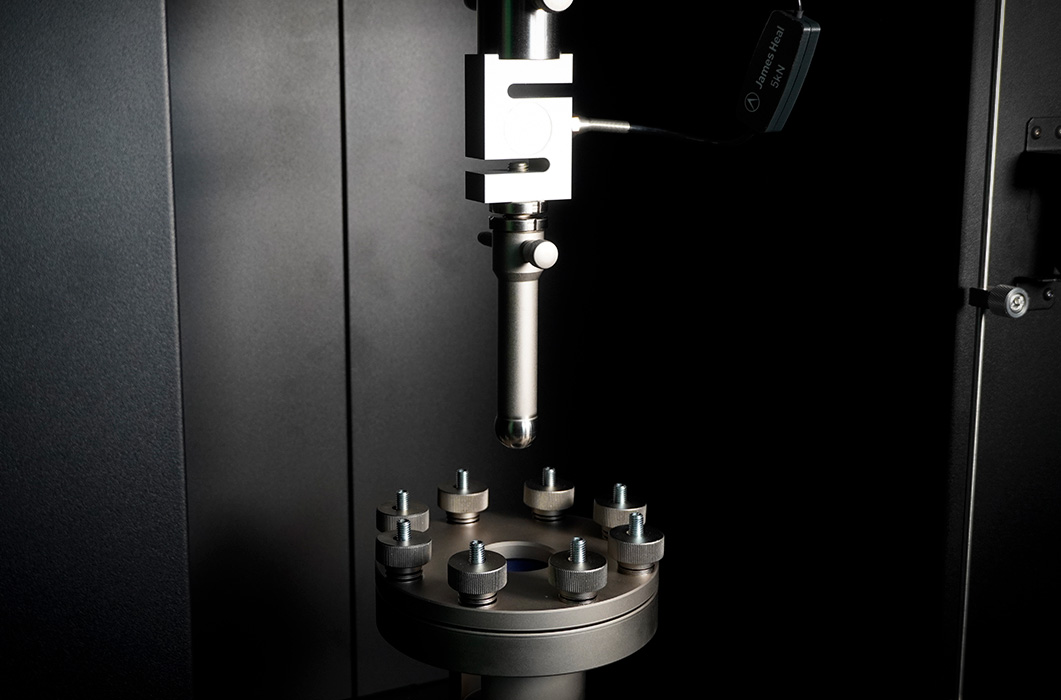

Simplicity and efficiency

User-centered design

Changing jaws and other grips is tool-free, keeping the Titan 25 simple and efficient to operate.

When loading grips or pneumatic grips, the jaws apply very light initial pressure, sufficient to hold the specimen yet safe for users.

The TestWise software automatically sets the parameters of the selected test, reducing set up time and eliminating user error.

Standards

Pre-loaded standards and test methods

Titan and TestWise have been developed based on a wide variety of national and international test standards and retailer methods.

TestWise is pre-loaded with over 750 standards and test methods, that can be further customised and saved by the user.

Safety guard

Operator health and safety

Our dual column universal testing machines can be supplied with a standard safety guard to prevent access by the operator to the testing area whilst the test is in progress. These have a rigid metal frame with integrated polycarbonate panels to allow the operator to view the test area from outside. Hinged doors are fitted with switch-activated interlock mechanisms that prevent system operation when open.

Guards for dual column test stands are supplied with new equipment and are pre-fitted to the tester at our factory, all ready for use when unpacked and installed.

Safety guards are supplied with CE marking and a Declaration of Conformity in accordance with several harmonised standards of the Machinery Directive 2006/42/EC, including BS EN ISO 12100:2010, BS EN ISO 14120:2015, BS EN ISO 14119:2013, BS EN ISO 13855:2010, BS EN ISO 13857:2008, BS EN ISO 13849-1:2015.

If the risk assessment for your application indicates protection from egress is also required, our engineers can offer a custom design to meet your needs.

Integrated safety guard

For enhanced operator safety, Titan 25 features an integrated front hinged door and back guard for operator protection during high capacity testing.

Testing applications

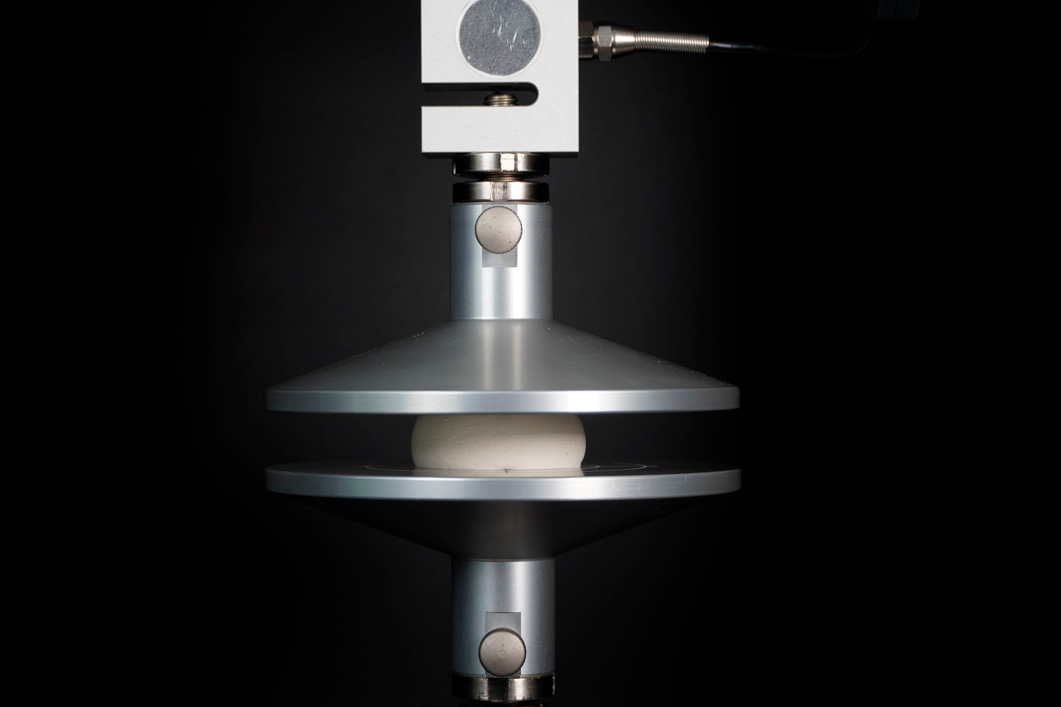

Titan 25 is a universal testing machine that has been designed for accuracy, safety and ease-of-use.

Universal strength testing covers many types of tension and compression testing, tests that pull specimen under tensile strength, and tests that compress specimen. Examples of some of the latest testing applications for Titan 25 include, safety footwear compression, safety harness and strap tensile strength, safety footwear sole penetration.

Titan 25 can test a range of applications including:

- nonwovens

- knitted and woven fabrics

- seams

- safety footwear

- ropes

- straps

- safety harnesses

Titan 25 is a dual column instrument, meaning larger samples can be tested across a full range of tests including tension, compression, stretch and recovery, tear, peel, adhesion peel, penetration and other applications. It has a vertical test space of 1200 mm and a space between columns of 460 mm.

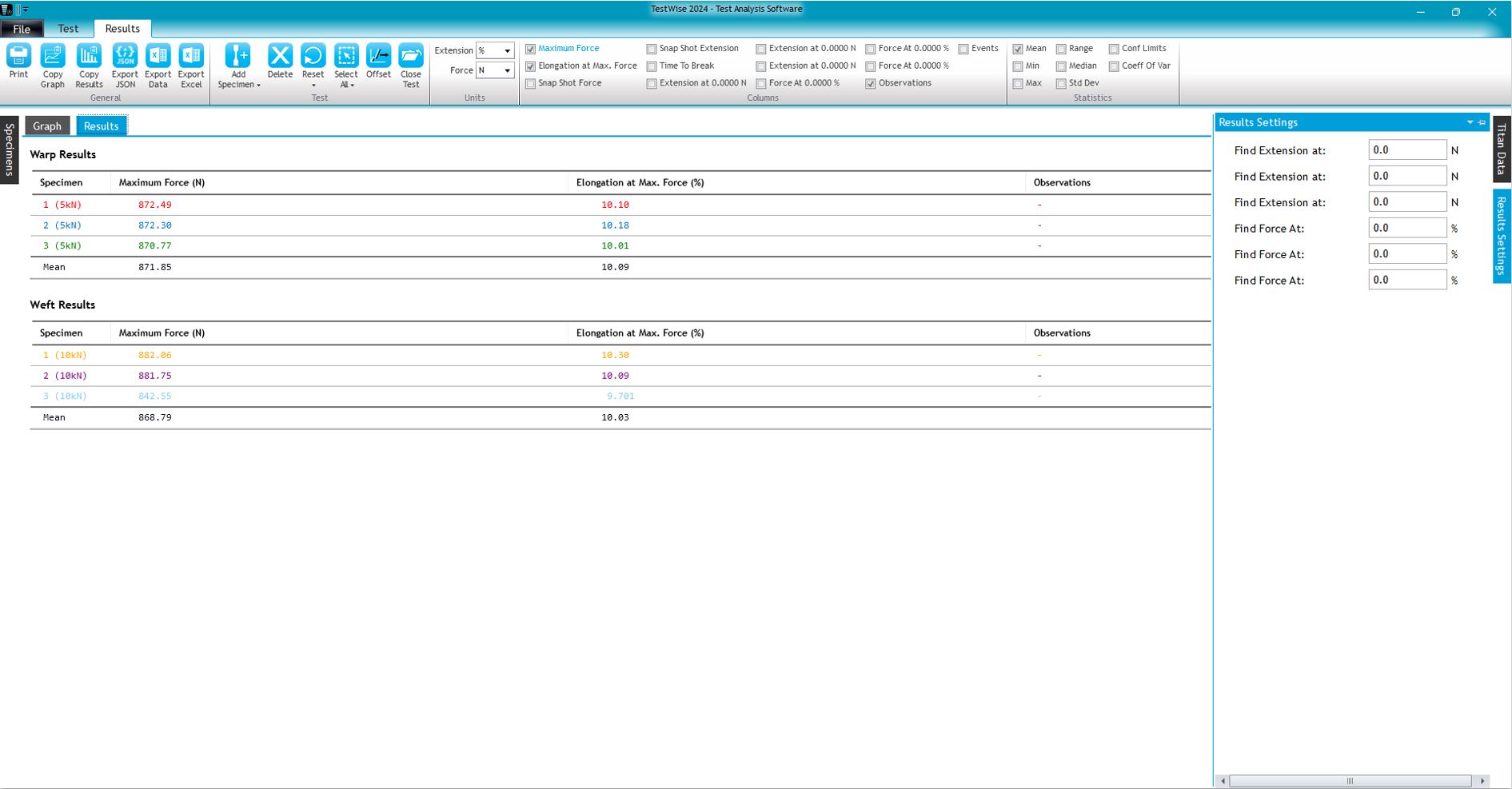

TestWise™

Advanced software made simple

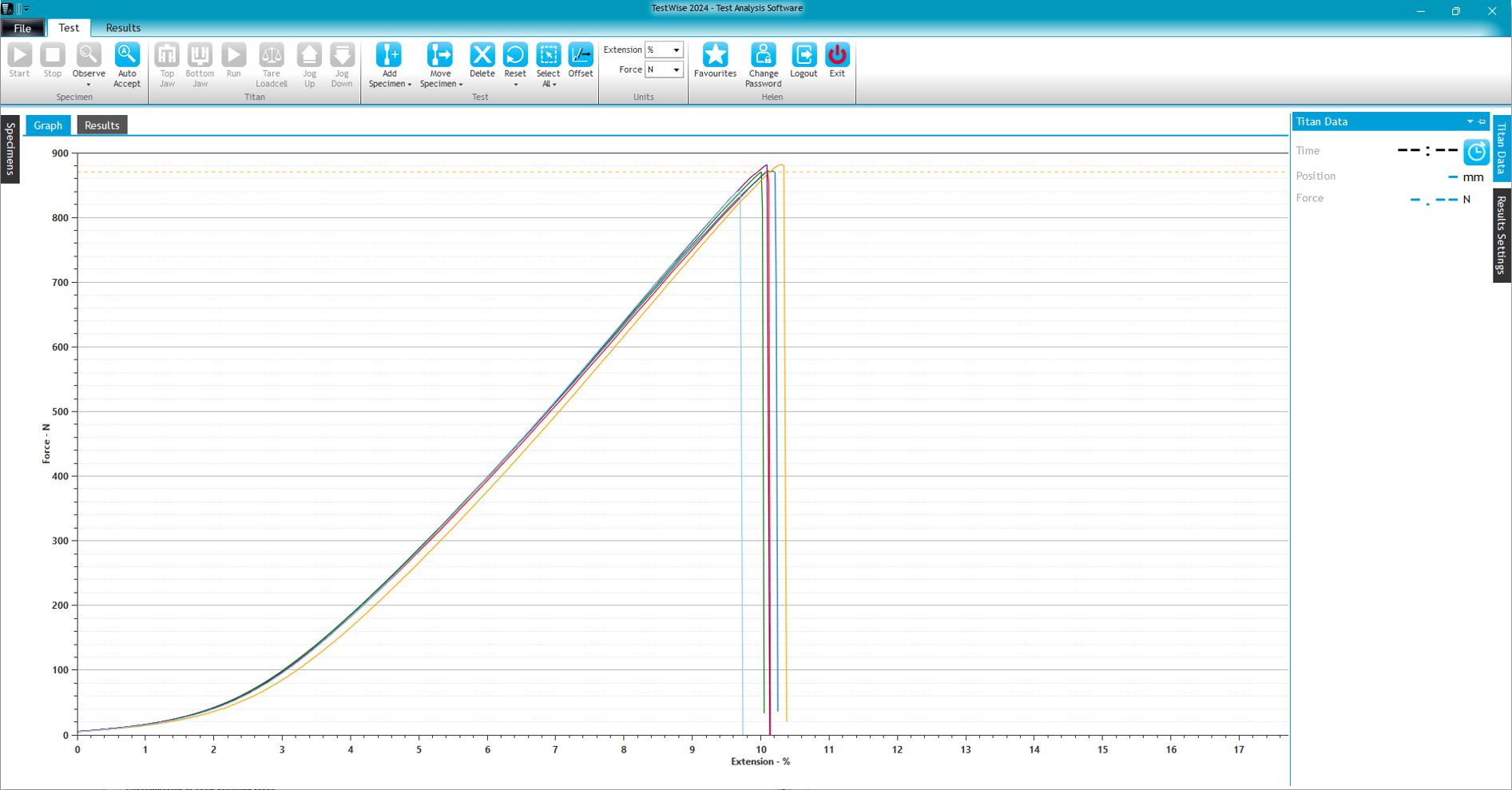

TestWise is a specially developed test analysis software that complements our Titan range of universal testing machines. The outstanding features of the software streamline the testing process, enhancing efficiency and result accuracy.

TestWise key features

Simple software interface

Titan is complemented by TestWise, an intuitive test analysis software requiring minimal training.

Streamlined search and favourites

Effortlessly locate standards using search filters and create personalised lists or favourite groups for easy access to frequently used standards.

Efficient testing process

The new 'Auto-accept' feature eliminates the need to switch between the instrument and computer, while defined observations (attributes) adhere closely to standards, ensuring specificity and relevance.

Effortless PDF saving

All reports can be swiftly saved directly to PDF, streamlining the final test report process.

Growing standards database

With over 750 pre-loaded standards and test methods, including ASTM, ISO, JIS, M&S, and Next, TestWise simplifies standard selection via the 'Filter' option.

Automatic parameter configuration

TestWise automatically test parameters, reducing test initiation time and eliminating user error.

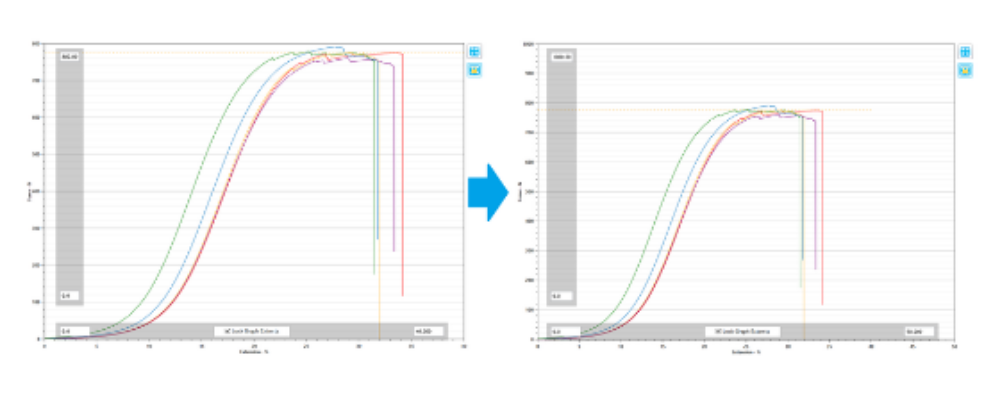

Enhanced calculations

A suite of calculations for sportswear, encompassing compression, energy loss, and hystersis for stretch fabrics with elastomeric yarns (Lycra, Spandex), facilitates precise analysis.

Real-time results monitoring

Real-time presentation of extension and force values facilitates result monitoring and immediate trend identification during testing.

Tailored statistical reporting

Customisable statistical reporting, including current mean values, offers instant trend visibility in specimen test results.

Seamless Excel export

Export test data to Excel with automatic graph generation, empowering users to conduct custom analysis and generate statistics.

Personalised standard settings

In addition to the extensive library of pre-loaded standards, users can customise and save standards to suit their specific testing requirements.

FAQs

What industries can benefit from using the Titan 25 as a universal testing machine?

The Titan 25 is versatile and can be used in textiles, automotive, aerospace, and construction industries for testing various materials' strength, durability, and performance. Titan 25 performs tensile and compression testing at our highest capacity yet, covering a broad catalogue of over 750 built-in standards.

How does the Titan 25 compare to other universal testing machines?

The Titan 25 offers precision, reliability, and ease of use, making it ideal for various testing requirements compared to other universal testing machines.

Can the Titan 25 perform both tensile and compression tests?

Yes, the Titan 25 is designed to perform tensile, compression, bending, and other tests, making it a true universal testing machine. TestWise for Titan provides a catalogue of over 750 built-in test standards.

Is the Titan 25 suitable for high-volume testing environments?

Absolutely. The Titan 25 is engineered for high throughput and consistent results, making it ideal for high-volume testing environments.

What materials can be tested with the Titan 25 universal testing machine?

The Titan 25 can test a wide range of materials, including textiles, plastics, metals, and composites, ensuring accurate results across different material types.

Material / End use

Technical Specification

Specifications are provided as a guideline only and are subject to change.

|

Titan 25 |

||

|---|---|---|

| Conditioned atmosphere recommended |

Yes |

|

| Positioning |

Bench standing |

|

| Capacity (Tension/Compression) |

25000 N |

|

| Accuracy |

|

|

| Speed accuracy |

±0.003% |

|

| Positional accuracy |

±0.00167 mm |

|

| Vertical stroke* |

900 mm |

|

|

*total vertical daylight/maximum vertical travel, measured without tooling |

||

| Space requirements** | ||

|

Height |

1576 mm (62") |

|

|

Width |

1090 mm (42.9") |

|

|

Depth |

603 mm (23.75) |

|

|

**measured without guard |

||

| Weight (approx) | ||

|

Instrument only |

230 kg (507 lbs) |

|

|

Instrument with guard |

261 kg (575.4 lbs) |

|

| Personal Computer (PC) Minimum Specification |

OS Windows® 8, Windows® 7, Windows® 10 Not compatible with Windows® XP or Windows® Vista Microsoft.NET 4.0 Framework is required, as advised by TestWise software during installation. HDD Minimum 250GB Ports 2x USB 2.0 ports |

|

| Frequently asked questions, online support and operator guides |

KnowledgeHub |

|